Well, my dear EOC friends, I have had my first problem with my Element after 96,000 miles.

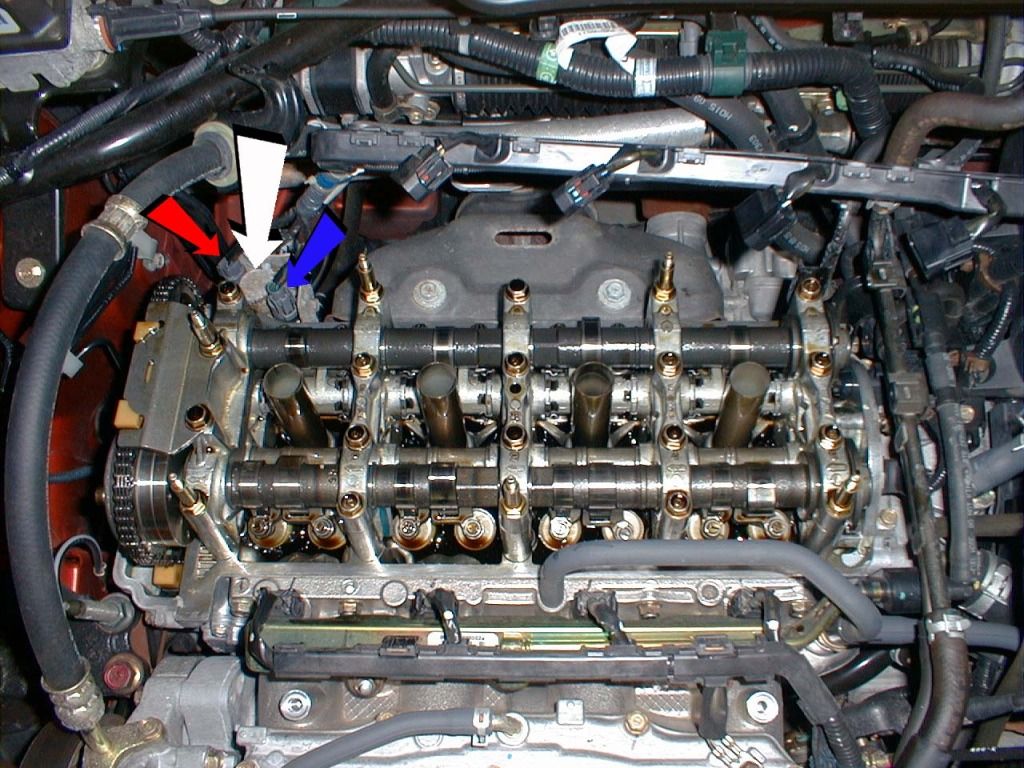

While driving down the road the other day, my malfunction indicator lamp came on. I instantly thought it was my gas cap, so I removed and reinstalled it and took off again, but I started cutting out and losing power. I instantly thought it was an 02 sensor, plugs, wires, or cat. convert. so I took it into Autozone this morning to have the code pulled and got [PO2646 Rocker Arm off or stuck] code. I had never heard of such a code, so I took it to my dealership for them to hook it up and see what they found.

I was wondering if anyone else has heard of this code or has any clue what could be the possible cause. I'll keep you updated.

While driving down the road the other day, my malfunction indicator lamp came on. I instantly thought it was my gas cap, so I removed and reinstalled it and took off again, but I started cutting out and losing power. I instantly thought it was an 02 sensor, plugs, wires, or cat. convert. so I took it into Autozone this morning to have the code pulled and got [PO2646 Rocker Arm off or stuck] code. I had never heard of such a code, so I took it to my dealership for them to hook it up and see what they found.

I was wondering if anyone else has heard of this code or has any clue what could be the possible cause. I'll keep you updated.